January 17, 2024 • 2 min read

Delivering construction and fabrication services to the Valhall PWP-Fenris project

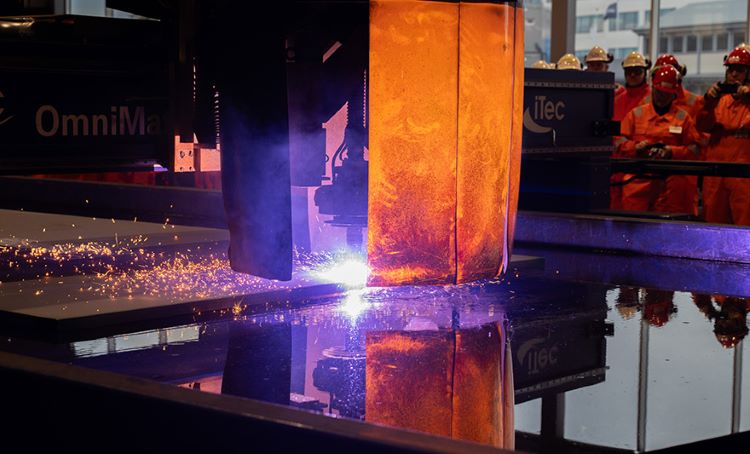

We’ve kicked off construction by cutting the first steel for Aker BP’s Valhall PWP-Fenris project at Worley Rosenberg in Norway.

Supporting life extension

The Valhall oil field has been in production since 1982 and the Valhall PWP-Fenris development project aims to extend the life of the field for another 40 years.

“Life extension projects like these are important as we bridge two worlds and accelerate towards more sustainable energy sources. We’re continuing to support our customers with their conventional assets to be able to provide the crucial energy security that Europe, and the world needs right now,” said Jan Narvestad, CEO at Worley Rosenberg.

Located in the Southern North Sea, the Valhall PWP-Fenris project is one of the largest development projects on the Norwegian shelf. And it includes a new centrally located PWP and an unmanned installation.

The total new reserves developed by the project are estimated to 230 million barrels oil equivalent. And production is scheduled to start in 2027.

Instead of gas turbines, the development has electrified its main power source and will leverage Valhall’s existing power-from-shore system with minimal emissions, estimated at less than 1 kg CO2/boe.

Collaborating with our industry peers

“We were awarded the two-year contract by Aker Solutions in August 2023 to deliver construction and fabrication services from our Worley Rosenberg facility. Our scope of work is to construct the topsides utilities module. A multidiscipline module mechanically completed and pre-commissioned,” said Narvestad.

“Working together with Aker Solutions, sharing expertise and facilities through industry collaboration is key as we navigate the energy transition and the future of the North Sea.”

Once complete, the five-story module will be 55 meters tall, 32 meters wide and 54 meters long and will weigh approximately 4,800 tonnes. It will be transported from Worley Rosenberg to Aker Solutions’ Stord yard for further hook-up to the production modules before sail away in summer 2026.

Providing a skilled workforce for now, and for tomorrow

The project also brings job security to those at Worley Rosenberg and people looking to learn and enter the workforce.

“The Valhall project is the largest new build we've had at Worley Rosenberg in 20 years. Over its two-year duration, 1,000 of our people will work on the project along with 50-60 apprentices,” said Narvestad.

“Our apprentices will complete their vocational training working on Valhall and will be an essential part of building and developing the future of the industry.”